شرکت ایلیانویت سازه میبد

ادامه مطلب

Update your building with the progress of the world

Autoclaved lightweight concrete, also known as AAC, is a type of gas concrete characterized by its numerous air-filled cells that serve as the main factor for its lightweight nature, thermal and acoustic insulation, and fire resistance. The main components are silica sand, cement, lime powder, gypsum, and aluminum powder, which are mixed with water according to specific formulas and models that are unique to each production plant.

The concept of AAC was first developed in 1924 by Dr. Axel Eriksson in Sweden at the Royal Institute of Technology in Stockholm and was later produced on a large scale in the 1930s and 1940s by various companies

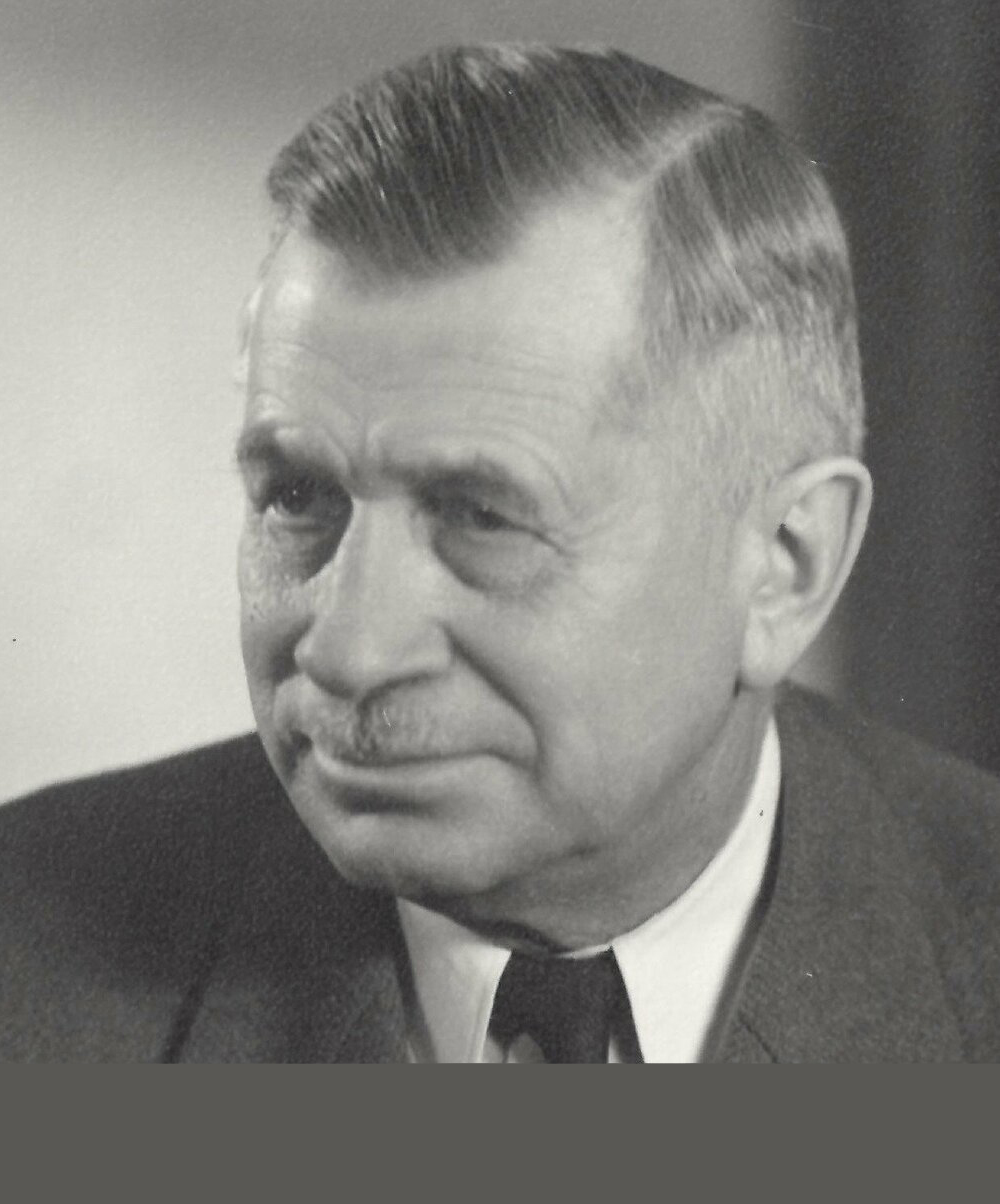

Dr. Axel Eriksson

In 1924, Dr. Axel Eriksson, an architect and professor of building technology at the Royal Institute of Technology in Stockholm, Sweden, was the first to introduce autoclaved aerated concrete. He developed autoclaved aerated concrete due to the shortage of wood caused by extensive deforestation and the need for alternative building materials

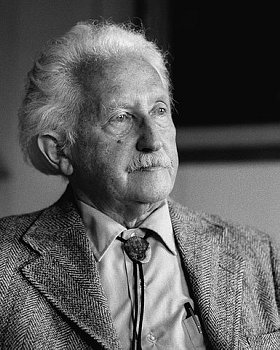

Joseph Hebel

Around 45 years ago in West Germany, Mr. Joseph Hebel, a construction engineer, mechanized the production process by designing an automated system for mixing, molding, cutting, and slicing the product, then adding rebar to increase its strength. Architects and building contractors quickly recognized the unique properties and advantages of this product, including its lightweight nature, high strength, and fire resistance, leading them to use it extensively in their projects.

Joseph Hebel

Dr. Axel Erickson

Historical Moments in the Evolution of Autoclaved Aerated Concrete

The darkest moments in history have occurred just before the dawn of significant discoveries. Similar groundbreaking innovations have shaped the evolution of autoclaved aerated concrete.

This narrative details the key discoveries and developments that led to advancements in the industry of autoclaved aerated concrete.

- Year 1880: The first attempts were made by Zemikov (V. Zemikov) to autoclave lime mortars under steam pressure, creating calcium silicate structures at lower water content. Later, similar processes were developed by W. Michaelis with improved outcomes.

- Year 1899: E. Hoffman from Czechoslovakia successfully produced a type of aerated concrete by introducing carbon dioxide into a mix of ground limestone, forming a unique aerated product.

- Year 1914: Aluminum powder was used as an aerating agent in mixtures, combined with calcium hydroxide (Ca(OH)2) by W. Aylsworth and F. Dyer from the United States, marking a significant milestone in material innovation.

- Year 1919: Grosahe from Norway further developed the concept by using metal powder as a gas-producing agent, advancing the technology behind autoclaved aerated concrete.

- Year 1920: After successful experiments by A. Eriksson and H. Kreüger, autoclaved aerated concrete was produced on an industrial scale by Carlso kalkbruk Skövde. This product was a combination of sand, lime, and cement, and was later named Durox.

- Year 1924: Eriksson, a Swedish architect, registered the first modern autoclaved aerated concrete product, developed by autoclaving under steam pressure.

- Year 1929: The industrial production of blocks in large quantities began with a patent from Yxhult Stenhuggeri AB in 1924, managed by C.A. Carlén. This product was later named YTONG in 1940.

- Year 1931: Arched doorways and reinforced segments were produced by Yxhult Stenhuggeri AB (later YTONG) using stretched, compressed, or arched rebar according to instructions by C. Forssell.

- Year 1933: The AAC mix was first proposed by the Swedish national group in 1933 and later refined by I. Eklund and L. Forsén to include all necessary components for building systems. The final product was named Siporex in 1937.

- Years 1933 to 1934: Both SIPOREX and YTONG brands started producing reinforced panels that later became a core component in building systems globally.

- Years 1935 to 1936: The YTONG brand, under H. Blomqvist, began producing autoclaved aerated concrete with a density of 500 kg/m³. This product gained popularity due to its high thermal insulation and low density, becoming a suitable building material by the late 1930s.

- Year 1942: Horizontal slicing of autoclaved aerated concrete was first developed by K.-G. Ringdahl in Sweden, inspired by the food processing industry. This innovation involved cutting green cake (pre-cured AAC) into slices for reinforcement.

- Year 1943: A new AAC mix design was introduced, and Hebel was recognized for its improvements in Memmingen, Germany.

- Year 1945: The use of rebar in the green cake of autoclaved aerated concrete began with J. Hebel, enabling the production of modern reinforced panels. These products re-entered production in 1948 after World War II disruptions.

- Year 1948: Complete revisions were made to AAC production in Emmering, led by J. Hebel, restoring production to its full capacity.

- Year 1953: A new horizontal slicing technique, developed by W. Sebardt for YTONG, was introduced and further advanced in the 1970s by R. Göransson for Siporex.

- Year 1955: The English Celcon company utilized high-grade fly ash (Type F) instead of sand, significantly reducing energy consumption for production. This substitution made it possible to produce products in less energy-intensive ways compared to traditional sand-based mixes.

- Year 1956: The YTONG brand refined the cutting process using the turning method, achieving higher precision and reducing variations in production. The development was led by the team of P. Jakobsson, W. Sebardt, and K.G. Öhrn.

- Year 1960: With the increased precision of block dimensions, the use of adhesive glue for bonding blocks was made possible, allowing for a maximum joint thickness of 3 millimeters.

- Year 1977: Tongue and groove designs were implemented by HEBEL, facilitating easier installation of the blocks. This feature, initially applied to panels after 1950, became standard.

- Year 1983: Handles were added to blocks by YTONG to ease handling and transportation during installation. This feature allowed builders to select this material for transporting construction materials over long distances without additional effort.

- Year 1992: The BCE technology began under the leadership of Lundvall & B.G. Hellers.

Introduction of Lightweight Concrete (AAC) in Iran

Autoclaved lightweight concrete technology was introduced in the 1950s by two private companies that established production lines for lightweight concrete products in Iran. These companies, founded by the late Hassan Hashemi and the late Akbar Bejestani Moghaddam, were the pioneers in bringing lightweight concrete technology to Iran.

Given that AAC products involve higher investment and relatively complex technology compared to traditional materials, their adoption was initially slow. However, following the prioritization of energy-saving policies after the Iran-Iraq War and the reduction of government subsidies, AAC products found a new place in the construction and industrial markets in Iran, leading to renewed production.